The savings and efficiencies gained with single-use systems in life sciences manufacturing are undeniable. Despite the upsides, manufacturing sites must consider and mitigate the negative impacts associated with single-use plastic disposal.

Pros and Cons of Single-Use Plastics in Biopharma Manufacturing

Single-use facilities have grown in popularity over the past two decades, bringing a range of benefits and savings:

- Flexibility in researching, developing, manufacturing, and marketing drug products

- Reduced cleaning and sterilization costs

- Decreased energy, water, chemical, electrical, heating, and air conditioning usage

- Smaller physical facility footprints

- Quicker setup of new processing lines

- Lower construction costs

- Efficiently increase capacity

- Ability to “start small” in the event a product doesn’t make it to market

- Repurposed savings toward other capital projects for growth and expansion

With the many benefits of single-use systems comes the obvious issue of disposal: what are companies to do with the tens of thousands of one-time-use bags, tubes, filters, containers, and other plastic components after they have served their purpose?

Based on recent estimates, the pharmaceutical industry produces roughly 30,000 tons of plastic annually – with that amount anticipated to balloon in the coming years.

Improving Waste Disposal to Protect the Environment

The complexity of the design of many single-use plastics presents an inherent disposal challenge. Disposable plastic bioreactor bags, for example, feature multiple layers comprised of different materials and chemicals that cannot be easily separated.

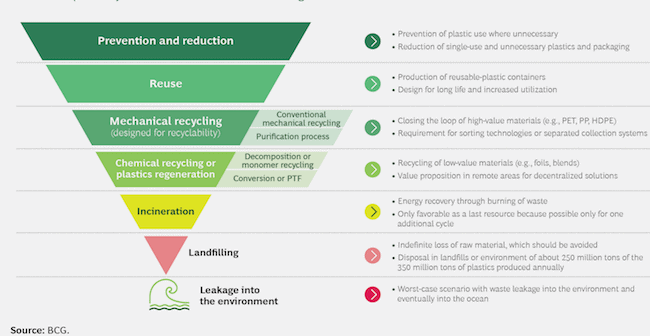

While companies are working to develop proper disposal methods via incineration and landfill, we as an industry should keep a focus on cost-effective ways to move up the pyramid of plastic waste management to lessen the environmental impact.

The graphic below from Boston Consulting Group summarizes the possible methods for solid waste management with examples of disposal options for single-use plastics.

Actionable Tips for Lessening the Environmental Impact of Single-Use Plastics

Your suppliers should be allies in finding the most responsible disposal methods for your single-use components and systems based on their established environmental management programs.

- Ask your suppliers for their recommended disposal methods for each component and follow their guidelines carefully to minimize environmental impact.

- Be mindful of how you choose your plastic suppliers and consider options that feature reusable or recyclable materials.

- Take the time to reach out to the waste management specialist inside your company to better understand how they are currently handling plastic waste and how you can be a conscious consumer.

With the proper planning and oversight, your company can realize the efficiencies of single-use systems in an environmentally friendly way.

Get It Done Right: Contact ICQ to Get Started

Want to discuss the implications of single-use systems on biopharma commissioning, qualification, and validation? Get in touch with our CQV experts today.