What reduces rework, lowers costs, and keeps your contract development and manufacturing organization (CDMO) cell and gene therapy (CGT) project on schedule? A robust commissioning, qualification, and validation (CQV) program in place throughout your project’s lifecycle is the answer.

Integrated CQV ensures that every step of the project — from the design concept to product release — meets compliance and regulatory requirements, the CGT product’s requirements, the manufacturing facility’s operational expectations, as well as your contracted companies’ requests without missteps or backtracking.

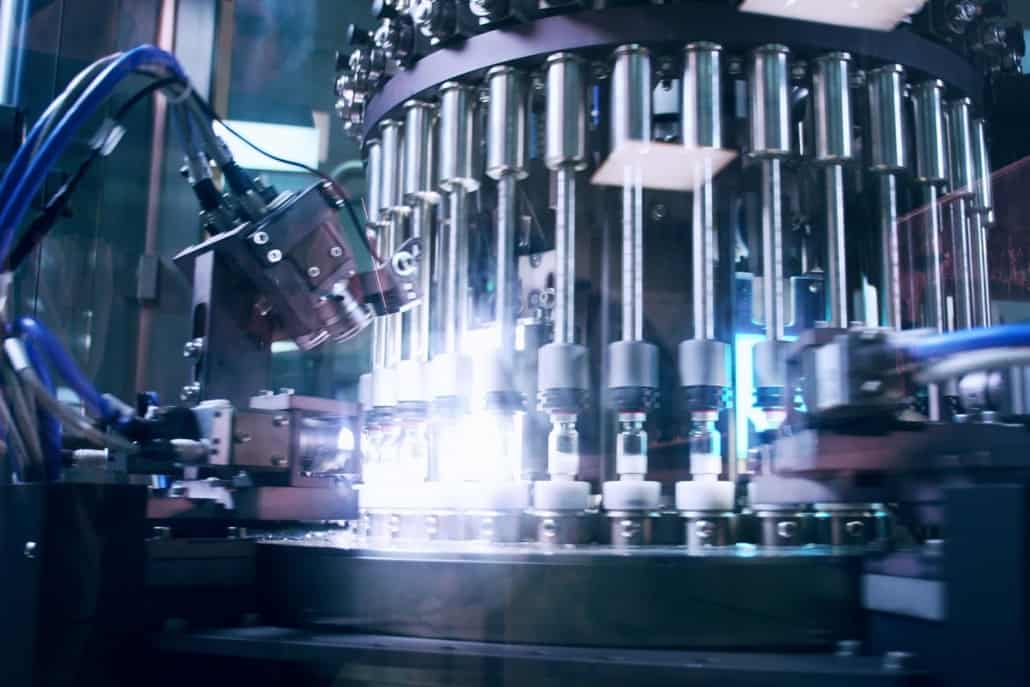

CDMOs play an essential role in CGT manufacturing and will continue to be a key player even after the pandemic. Whether you’re building a facility from scratch or retrofitting a current facility, consider these CQV practices as you enter every phase of your project’s lifecycle.

Preparing to Break Ground

Having a robust, efficient, and well planned CQV program from the get-go can save your CDMO from costly oversights. Before getting started on a facility project, consider taking the steps below:

- Generate CQV procedures that meet current regulations as well as follow current guidelines with an integrated commissioning and qualification program to ensure compliance and also execute the program efficiently. Check out our specific recommendations here.

- Create a detailed project plan with schedules, resources, key milestones, and scope of work.

- Write a project plan with identified owners for each core process and activity.

- Craft a communication plan with your core team and stakeholders to understand communication preferences and requirements. This way you can reference a central document in case of miscommunication.

- Establish a follow-through system and identify potential risks that need addressing.

Want more? Read how ICQ supported Paragon Bioservices with construction coordination and CQV program development to achieve milestone dates, remain on schedule, and be ready for regulatory inspections.

Preparing for Operational Readiness

Operational readiness and CQV go hand in hand. Being operationally ready means you’ve not only thought through potential risks but have built in internal quality controls to mitigate those risks. Risk is a loaded term and can be attributed to anything from a contractor delay to a reduction in staffing resources.

However, there are some other factors to keep in mind when preparing your operational readiness plan. Ajinomoto Bio-Pharma Services has a great list of questions they tell companies to consider when deciding on a CDMO for their bioprocessing needs. Is your organization prepared to answer these questions satisfactorily?

- What quality systems does the CDMO have in place?

- How is troubleshooting handled during scale-up?

- Can analytical testing be done on-site?

- Does the CDMO allow people in a plant (PIP)?

- What is the CDMO’s project management and communication style?

Preparing for Licensing and Regulations

Staying current and filing timely applications with the right regulatory bodies is a big job in itself since the details for each project add complexity to an already complicated undertaking. CDMOs need to know all licensing requirements, stay aware of new regulations, and deliver new reports that keep projects moving to conclusion.

ICQ follows the latest best practices outlined by the FDA, EMA, ICH, WHO, ISPE, PDA, ISO, and dozens of other global regulatory agencies to ensure your project meets all regulatory requirements while adhering to site-specific procedures and policies. ICQ is here to be your guide when your CDMO is ready to apply with the necessary regulators, including supporting the inspection and reinspection if needed.