The biotech and pharmaceutical industries are highly risk-averse and must abide by strict regulations, and rightfully so—any minor mishap can lead to an unsafe or ineffective product. One way to avoid risk, adhere to industry regulations, and ensure the safety and efficacy of products is through temperature mapping.

Temperature mapping is critical for biotech and pharmaceutical companies that produce and distribute temperature-sensitive products. Temperature fluctuations during storage and transportation can severely impact the quality of these products. Therefore, it is necessary to ensure that the temperature remains stable, uniform, and within the acceptable range throughout the entire supply chain.

Who And What Needs Temperature Mapping?

Any company that complies with the FDA and adheres to GXP practices must perform temperature mapping on equipment such as refrigerators, freezers, incubators, autoclaves, and stability chambers.

Additionally, if they store temperature or humidity-sensitive products in a warehouse, temperature mapping of that facility is required to ensure proper and consistent temperature and humidity.

Manufacturers must perform temperature mapping on:

- New equipment

- Recently repaired equipment (depending upon the extent of the repairs)

- Recently moved equipment (depending upon the move details)

How Does Temperature Mapping Work?

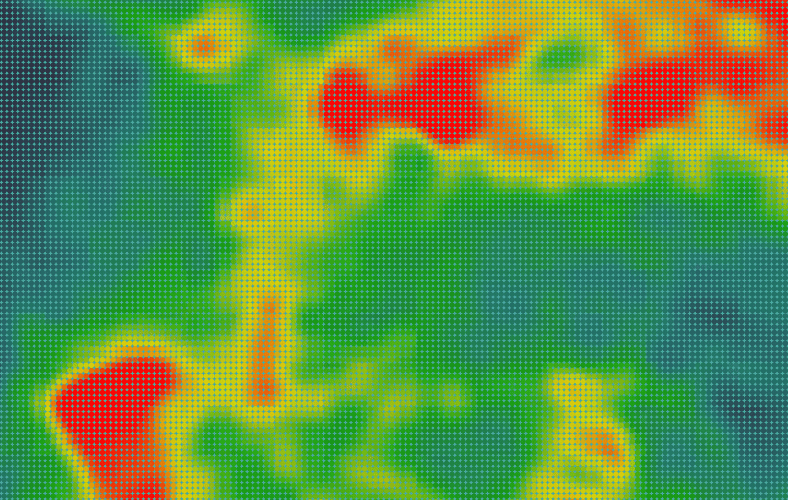

Temperature mapping involves measuring the temperature at various points in a storage or transportation system to identify any hot and cold spots or areas with higher humidity.

The parameters that temperature and humidity must fall within are predetermined by regulating bodies and/or the specific piece of equipment. Identifying these areas is crucial as they can ultimately lead to a compromised product, and the cost of replacing damaged products can be significant.

There are several steps involved in temperature mapping. The first step is to identify the critical points within the storage or transportation system where temperature measurement is necessary. These critical points could include the storage area, the loading dock, the shipping container, and the transport vehicle.

Once you have identified critical points, the next step is to install temperature sensors at each point. Temperature mapping professionals will calibrate and validate these sensors to ensure accuracy and reliability.

After installing sensors, data loggers will record temperature readings over a set period of time. This period should be long enough to capture the temperature fluctuations that occur during typical storage or transportation conditions. Typically, 24 to 48 hours is sufficient for most applications.

Then, manufacturers can analyze this data to identify any areas of concern. This analysis helps identify areas where temperature control is insufficient and take corrective action to address these issues.

To fix a specific area that’s too hot, cold, or humid, the equipment may need repair, or it could be something as simple as improper packing that led to a product blocking a vent.

How Often Does Temperature Mapping Occur?

It’s important to note that temperature mapping is not a one-time occurrence. Manufacturers should perform these tests regularly to ensure the quality of their products and that their storage or transportation system remains in compliance with regulatory requirements.

It is common for sterilization equipment to undergo a re-qualification cycle every six months or annually. However, the frequency of re-qualification for storage areas and warehouses varies significantly, ranging from less than once per year to as long as five years.

Warehouses may also need additional attention during extreme seasons, such as winter and summer, as the external temperatures may alter the conditions inside the facility.

Finding The Right Temperature Mapping Partner

It’s common for manufacturers to outsource their temperature mapping to experienced professionals. However, deciding who to choose based on your specific equipment, facility, or product can be difficult.

Being part of the Ellab family allows us to provide comprehensive and customized temperature mapping services to fit any company’s unique needs. Whether you need staffing for a specific project or fill-time staff augmentation, we can help.