A compromised sterilizing grade filter can lead to contamination, equipment failure, and dangerous end-products unsuitable for use.

Integrity testing helps biopharma companies avoid these undesirable consequences by ensuring their sterilizing grade filters stay intact before and during use. It’s an essential aspect of creating safe products, as well as a regulatory requirement.

There are three standard filter integrity testing methods. The type of equipment, specifications, and conditions you are working with will inform which test you use.

For example, a major deciding factor is whether or not the filter is hydrophilic or hydrophobic. Hydrophilic filters are water attractive, and hydrophobic filters are water repellent. Due to the fundamental differences of each, they require different approaches to testing.

The two standard tests used for hydrophilic filters are diffusion and bubble point tests. While we previously discussed diffusion tests, let’s focus on bubble point tests.

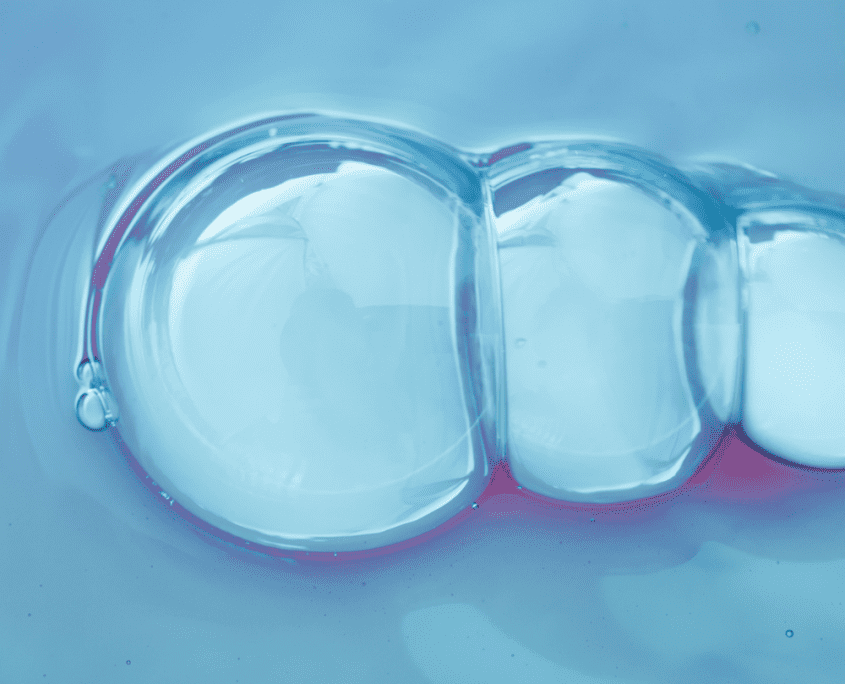

How Does a Bubble Point Test Work?

First, you wet the filter with water. Then, you must apply increasing pressure of air to the upstream side of the filter until it overcomes the water tension of the largest pore in the system. Then, once it forces the water through the pore and air flows freely through it, you will find the “bubble point.”

The flow rate of air diffusing through the saturated filter membrane is monitored and measured throughout this process. After completion, you can compare your findings to any predetermined values that indicate correct functionality. If your findings meet these values, your filter is functioning properly.

It’s important to note that different filter manufacturers and specific filter types have different predetermined values that indicate functionality. Typically, you can find this information in technical documentation for the filter you are testing.

Similar to other filter integrity tests, you can perform a bubble point test manually or use modern equipment to automate the testing process. With many organizations striving toward Pharma 4.0, automated filter integrity testing has become more prevalent.

With automated bubble point tests rising in popularity, this approach has become fast, efficient, and accurate. Not to mention, automation creates easily reproducible and traceable processes, helping you prepare for audits and boosting your regulatory inspection readiness.

While bubble point tests are commonly used for hydrophilic filters, you can also use them to test hydrophobic filters. However, the process differs. When testing a hydrophobic filter, the wetting agent cannot be water because, as previously mentioned, it will repel water. Instead, we typically use isopropyl alcohol as the wetting agent.

Key Considerations for Using a Bubble Point Test

Because you are measuring the surface tension of water and finding at what point it breaks through, it is of the utmost importance to be aware of factors that need to remain controlled as they can lead to inaccurate readings.

These factors include:

- The temperature of the water

- What type of water you are using (avoid using hard water that contains minerals or water that has cleaner in it)

- The proper wetting of the filter as dry pores and premature air flow will cause a test failure

This test also has its limitations. If you are dealing with an extensive filter system, there’s a chance that the accuracy of the true bubble point will be compromised.

Need Help with Your Filter Integrity Testing?

The bubble point test is one of many tests used by biopharma companies to ensure the integrity of their filters.

Knowing which to use for your specific situation, product, and goals isn’t always easy. Our team of pharma qualification and validation experts can help you make the right decision and guide you through the entire process.