Five Keys to Problem Solving

- Define the problem / Focus on the Root Causes (Not Symptoms)

There are many techniques for getting to the heart of a problem (flowcharts, cause and effect diagrams, root cause analysis, the 5 Why’s), but the important part is to be able to identify when a problem is a root cause or just a symptom of a deeper problem. There may be multiple root causes. Experience is key to being able to successfully define a problem. Make sure the right people are in the room, and if you feel as though something is being missed, remember that you work for a growing consulting firm that has years of collective experience. Leverage that experience.

- Look to turn off all Root Causes / Generate alternative Solutions

If we only look to resolve one root cause (for a problem with multiple root causes) the problem will likely resurface shortly, but perhaps appear to be a new or different problem. We want to find solutions that effectively “turn off” all the root causes. We also want more than one solution for any problem. This may be difficult for those of us with many years of experience, but showing patience in these early sets of problem solving can yield much higher dividends.

- Evaluate and Select Solutions

Some things to consider when evaluating and selecting a solution might be:

- What chance does a solution have to solve the problem without causing unanticipated problems? We might want to find simple solutions that affect as few contributing factors as possible. This will limit the impact to processes that are not currently experiencing a problem.

- Will all individuals affected by the problem accept this solution? This may be a tough question to gauge, but if we have the right people in the room, we can find a solution that works for everyone.

- Is it likely that the solution will be implemented? This goes hand in hand with the bullet above. If a solution will be difficult to implement, it’s more than likely that the problem will persist.

- Does the solution fit within organizational constraints? Again, if a solution doesn’t work for the client, they are not going to implement it.

- Implement and follow up

Make sure to thoroughly plan the implementation of any solution: include goals, roll-out programs, CAPAs and plan the allocation of resources. Success will depend on getting the people affected by the problem involved in the solution. Feedback channels should be facilitated and welcomed as a way to continuously monitor the effectiveness of any change.

- Audit Results of Problem Solving

Once a problem has been solved within an operation, we should audit the affected process to make sure we have actually solved, not just contained, the problem. An assessment would also benefit the organization to figure out why a solution was effective or ineffective.

By effectively helping our clients to solve problems within their operations, we can create a good working relationship that goes beyond commissioning and qualifying systems.

Written By: Steve Graham, Consultant II

ICQ Consultants, Corp.

Join our network, follow us and share this on LinkedIn, Google +, Twitter and Facebook so you can see other new and exciting news and discussions being posted by ICQ Consultants

then we can check that off and we are on our way. Well maybe? Too often we overlook a key component for a successful qualification. Proper calibration starts with the manufacturer’s design and operation of the equipment. We purchase equipment for GMP use and fast track the qualification to meet the project deadline. The service manual usually provides a calibration method based on the design and operation of the equipment. In our expedience we sometimes neglect details that we may consider mundane and jump right to our one size fits all method of calibration for related equipment, calibrate and assume success.

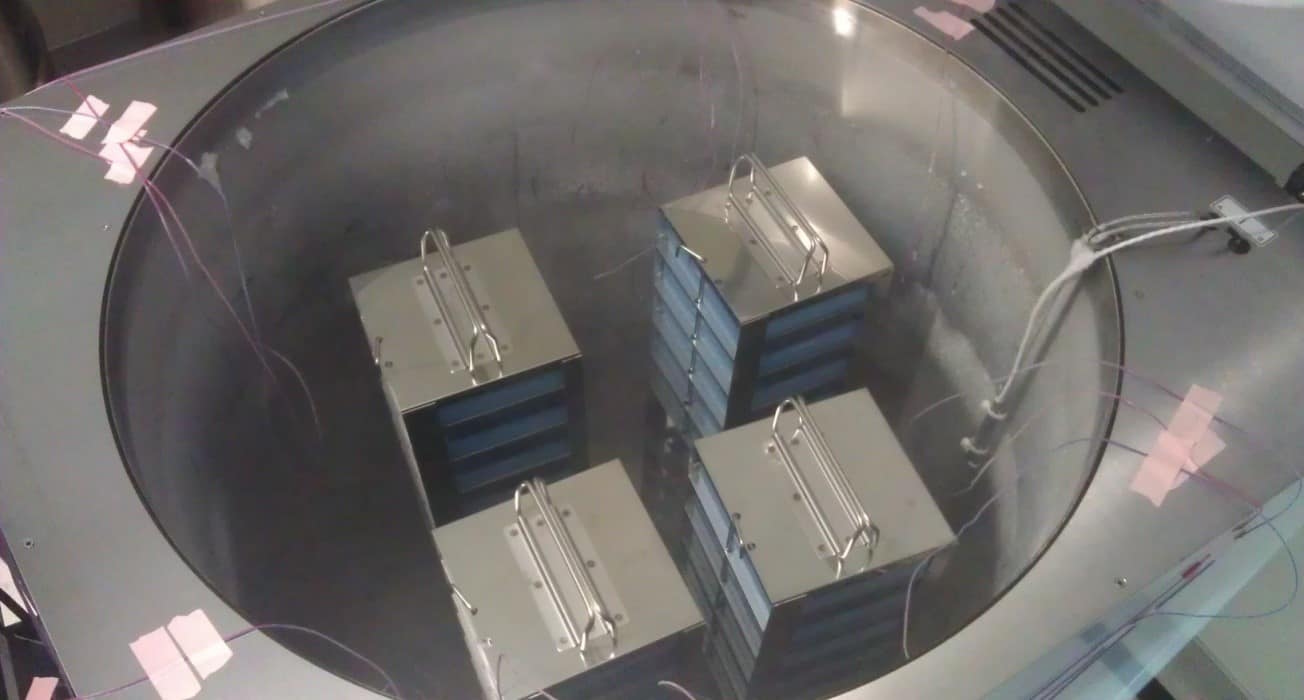

then we can check that off and we are on our way. Well maybe? Too often we overlook a key component for a successful qualification. Proper calibration starts with the manufacturer’s design and operation of the equipment. We purchase equipment for GMP use and fast track the qualification to meet the project deadline. The service manual usually provides a calibration method based on the design and operation of the equipment. In our expedience we sometimes neglect details that we may consider mundane and jump right to our one size fits all method of calibration for related equipment, calibrate and assume success. The service manual clearly stated that the unit be calibrated to the center of the chamber. It just so happened that the client had their calibration contractor performing “6 month” calibrations on the existing identical freezers in the lab. I curiously asked the technician where in the chamber he was placing the calibration temperature test probe. His answer was that they always place the test probe adjacent to the unit’s controlling probe. The controlling probe for these freezers were located in the back right hand side corner of the middle shelf. This location also happens to be the coldest point in the unit. With a quick demonstration the client was able to see that there was almost a 2° C difference in the recorded temperature in the center of the chamber versus the temperature reading with the calibration temperature test probe placed adjacent to the controlling probe. The client’s SOP stated to place the calibration temperature test probe adjacent to the controlling probe of the unit and directed that the three new units be calibrated as such due to the project time constraint and not being able to revise the calibration SOP in time. Our demonstration proved almost a 2° C difference and by calibrating to the coldest point in the unit would jeopardize the acceptance criteria temperature span on the warm side. The first two brand new freezers failed qualification and could not maintain temperature criteria. The warmest locations in the freezer were more than 10° C less than the required set-

The service manual clearly stated that the unit be calibrated to the center of the chamber. It just so happened that the client had their calibration contractor performing “6 month” calibrations on the existing identical freezers in the lab. I curiously asked the technician where in the chamber he was placing the calibration temperature test probe. His answer was that they always place the test probe adjacent to the unit’s controlling probe. The controlling probe for these freezers were located in the back right hand side corner of the middle shelf. This location also happens to be the coldest point in the unit. With a quick demonstration the client was able to see that there was almost a 2° C difference in the recorded temperature in the center of the chamber versus the temperature reading with the calibration temperature test probe placed adjacent to the controlling probe. The client’s SOP stated to place the calibration temperature test probe adjacent to the controlling probe of the unit and directed that the three new units be calibrated as such due to the project time constraint and not being able to revise the calibration SOP in time. Our demonstration proved almost a 2° C difference and by calibrating to the coldest point in the unit would jeopardize the acceptance criteria temperature span on the warm side. The first two brand new freezers failed qualification and could not maintain temperature criteria. The warmest locations in the freezer were more than 10° C less than the required set- point. The devastated client quickly revised their calibration SOP and re-calibrated to the center of the chamber with all three new freezers then able to pass qualification.

point. The devastated client quickly revised their calibration SOP and re-calibrated to the center of the chamber with all three new freezers then able to pass qualification.

It’s a good idea to improve your organizational skills, be more effective at meeting deadlines, or learn to prioritize more efficiently. Improving these skills will increase your value and make you more marketable regardless of your field.

It’s a good idea to improve your organizational skills, be more effective at meeting deadlines, or learn to prioritize more efficiently. Improving these skills will increase your value and make you more marketable regardless of your field. but also for networking. Find the conferences that are most applicable to people who work in your industry and go. Not only will you learn about new techniques, skills, and industry standards within your profession, but you’ll also make new contacts with the same interests. New contacts within your field have the potential to be invaluable assets to your career growth. You never know where someone you know may end up in the future and what opportunities they may offer you as a result of your relationship with them.

but also for networking. Find the conferences that are most applicable to people who work in your industry and go. Not only will you learn about new techniques, skills, and industry standards within your profession, but you’ll also make new contacts with the same interests. New contacts within your field have the potential to be invaluable assets to your career growth. You never know where someone you know may end up in the future and what opportunities they may offer you as a result of your relationship with them.

The temperature across all areas of an environmental chamber will not usually be uniform and will vary to a certain degree. Possible areas that could vary in temperature could be near the door, on the wall, below the compressor area or near a fully loaded rack versus an empty rack.

The temperature across all areas of an environmental chamber will not usually be uniform and will vary to a certain degree. Possible areas that could vary in temperature could be near the door, on the wall, below the compressor area or near a fully loaded rack versus an empty rack.

All too often otherwise successful projects in the GMP space encounter scheduling and compliance challenges for a simple reason: A failure to properly integrate Quality Systems and compliance requirements into the project planning effort. Complex build outs, engineering efforts and process changes can all fall flat in the final hour for these simple reasons. There are few things more frustrating than completing months of technically challenging work on budget and on schedule only to see the project slip because a quality record was not in the correct state or a required reviewer was missed.

All too often otherwise successful projects in the GMP space encounter scheduling and compliance challenges for a simple reason: A failure to properly integrate Quality Systems and compliance requirements into the project planning effort. Complex build outs, engineering efforts and process changes can all fall flat in the final hour for these simple reasons. There are few things more frustrating than completing months of technically challenging work on budget and on schedule only to see the project slip because a quality record was not in the correct state or a required reviewer was missed. So what can firms do to avoid this frustration? How can we ensure success in meeting timelines, accounting for the final 2-5% of the project effort? The answer is to integrate the quality systems into the project from the earliest stages. This answer seems simple, but requires a dedicated effort and the right people to be involved at the right time throughout project planning and execution.

So what can firms do to avoid this frustration? How can we ensure success in meeting timelines, accounting for the final 2-5% of the project effort? The answer is to integrate the quality systems into the project from the earliest stages. This answer seems simple, but requires a dedicated effort and the right people to be involved at the right time throughout project planning and execution. uring the right resources are informed and consulted. Identify clearly the quality system requirements and associated timelines, integrate these as deliverables and milestones into the overall plan and schedule. Keep lines of communication open with Quality as project variances will inevitably occur, adjust not only the technical side of the project plan but the associated quality system and documentation requirements. A consistent integrated approach ensures compliance, timely project completion and eventual turnover.

uring the right resources are informed and consulted. Identify clearly the quality system requirements and associated timelines, integrate these as deliverables and milestones into the overall plan and schedule. Keep lines of communication open with Quality as project variances will inevitably occur, adjust not only the technical side of the project plan but the associated quality system and documentation requirements. A consistent integrated approach ensures compliance, timely project completion and eventual turnover. Mike Gatta, Al Guarracino, and Victoria Hayes attended last night’s PDA meeting as sponsor representatives, staffing an information table during the networking reception. Due to the popularity of the topic, Regulatory Inspection Trends, the conference room at the Hilton in Woburn, MA was nearly

Mike Gatta, Al Guarracino, and Victoria Hayes attended last night’s PDA meeting as sponsor representatives, staffing an information table during the networking reception. Due to the popularity of the topic, Regulatory Inspection Trends, the conference room at the Hilton in Woburn, MA was nearly  full of attendees. The first speaker was Edmund Mrak of the FDA, who shared some of the most frequent types of 483 citations. He offered some insights into some very avoidable findings. During his presentation he fielded many questions from the audience on this engaging topic. Next to speak were David Sencabaugh and William Frisch, both from the Massachusetts Board of Registration in Pharmacy. These gentlemen shared updates about compounding pharmacies and the new practices that were put into place in the wake of the fungal meningitis fatalities traced to the New England Compounding Pharmacy. ICQ would like to thank everyone who stopped by and visited our table.

full of attendees. The first speaker was Edmund Mrak of the FDA, who shared some of the most frequent types of 483 citations. He offered some insights into some very avoidable findings. During his presentation he fielded many questions from the audience on this engaging topic. Next to speak were David Sencabaugh and William Frisch, both from the Massachusetts Board of Registration in Pharmacy. These gentlemen shared updates about compounding pharmacies and the new practices that were put into place in the wake of the fungal meningitis fatalities traced to the New England Compounding Pharmacy. ICQ would like to thank everyone who stopped by and visited our table.