What is Temperature Mapping and why is it important?

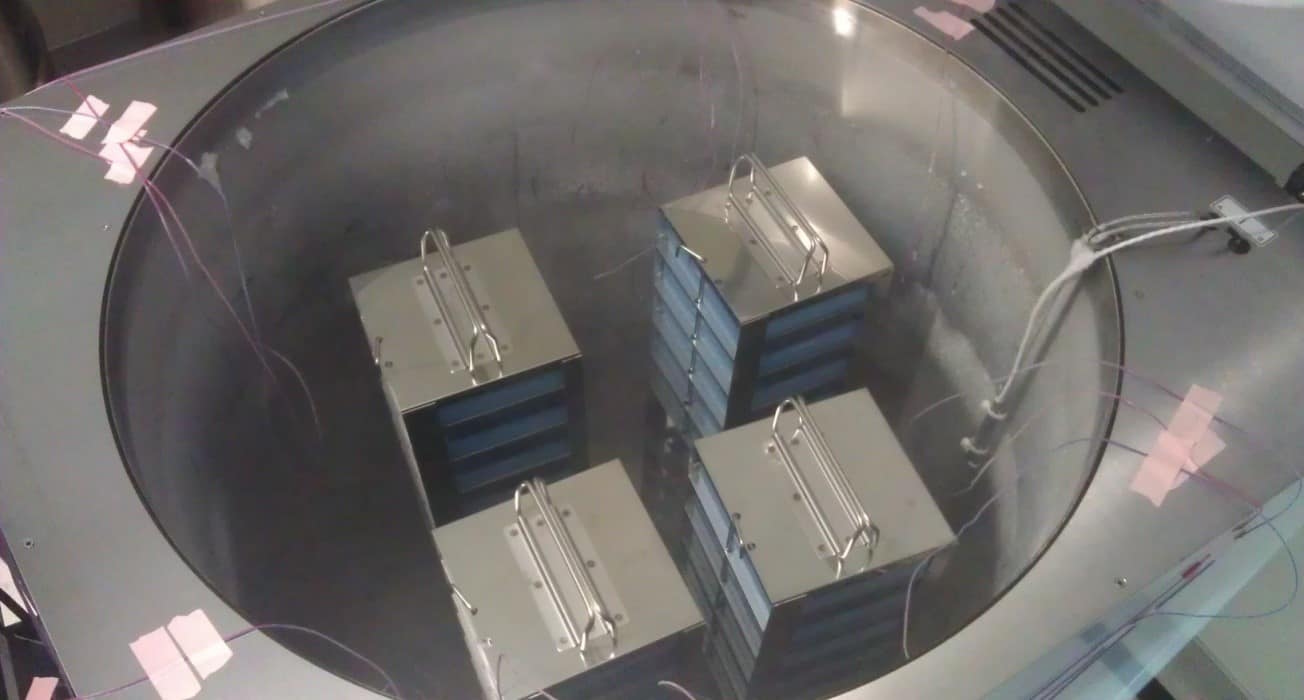

Temperature Mapping is the process by which an entire area of an environmental chamber is continuously monitored, recorded and analyzed over a predetermined amount of time under real operating conditions. Environmental chambers vary from cryogenic freezers and incubators to refrigeration trucks.

In all such conditions, hot spots are created and could potentially affect product quality. In some cases, areas of the chamber that are too cold can have adverse effects on product quality. Environmental chambers that cannot maintain the correct temperature ranges could cripple or damage a product and then halt the production of said product.

The solution for this is to execute temperature mapping qualification written and designed for environmental chambers. Testing should be completed for both an empty chamber and when the chamber is loaded with the appropriate product placebo (perhaps several loaded chamber qualifications if your chamber stores a variety of products). Also, it is recommended (depending on your geographic location) to perform a qualification/re-qualification for the location of storage for refrigeration trucks during both the hottest and coldest times of the year. This would ensure that your environmental chambers are fully qualified for product storage and safety.

By: Tony Puleo, Consultant

ICQ Consultants, Corp.

Join our network, follow us and share this on LinkedIn, Google +, Twitter and Facebook so you can see other new and exciting news and discussions being posted by ICQ Consultants.