Temperature Controlled Systems: Refrigerators and Freezers

Have you ever completed the temperature mapping / qualification testing for a walk-in refrigerator or freezer and felt good about the data? That is until someone asked you to relate what the numbers mean in relation to the system and what was happening inside the unit. You knew the results met the acceptance criteria, but maybe weren’t so sure how they related to system performance.

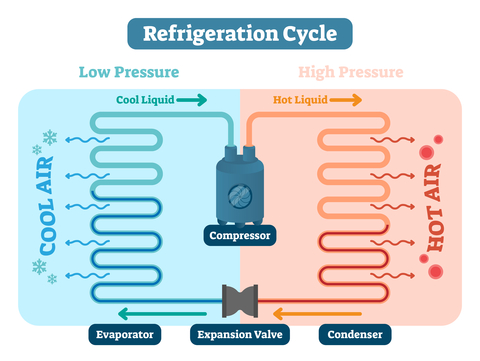

Cooling and Heating…How Does It Work?

All Temperature Controlled Units (TCUs) have five main components:

- Microprocessor

- TCU Engine

- Compressor

- Condenser

- Evaporator

An area containing all of the main components listed above with the exception of the evaporator is located outside the controlled environment space (e.g. outside the cold room).

The compressor pumps refrigerant through the temperature-controlled system. It works with the engine to increase pressure triggering the refrigerant to change phase from a gas to a liquid. Due to the phase change the refrigerant will heat up during compression. The liquid refrigerant is then pumped to the condenser. The condenser removes the heat absorbed by the refrigerant from the compressor and temperature-controlled area. As the heat is being absorbed the refrigerant approaches thermal equilibration with the ambient air outside the controlled environment space. Once the refrigerant has been cooled to a liquid it flows through an expansion valve into the evaporator. The evaporator then transfers heat out of or into the controlled environment space to control the area temperature. The refrigerant changes back to a gas as it absorbs heat. The heated refrigerant then flows back through the compressor and the cycle starts over. As you might have guessed, the heating process of a refrigeration unit is usually the opposite of the cooling process. The evaporator becomes the condenser and vice versa.

What about the defrost cycle you ask?

The defrost cycle is used to prevent the system from forming ice. When and how often the defrost cycle is used is based on measurements of the coils temperature at given time intervals. A timer closes the circuit which then allows air to flow to a temperature sensor. If the temperature falls within the temperature range that would allow the formation of ice, the unit will start a defrost cycle. Typically, an electric heater is used to defrost the evaporator. Obstruction of airflow due to evaporator icing may also trigger the defrost cycle to begin.

Parting Thoughts

Written By: Nathan Roberge, Consultant III

Reference:

- Active Temperature-Controlled Systems: PDA Technical Report No. 64; 2013